A single number cannot summarize the lifespan of water supply pipes. It ranges from 70 years in civil buildings to less than 10 years in industrial scenarios. The differences are due to four core variables: material performance, environmental pressure, water quality characteristics, and maintenance level. This article will compare and analyze the durability of water supply pipes in different scenarios, and focus on analyzing the true lifespan of copper pipes, a popular material for home decoration.

1. Comparison of Lifespans in Three Major Scenarios: Household > Commercial > Industrial

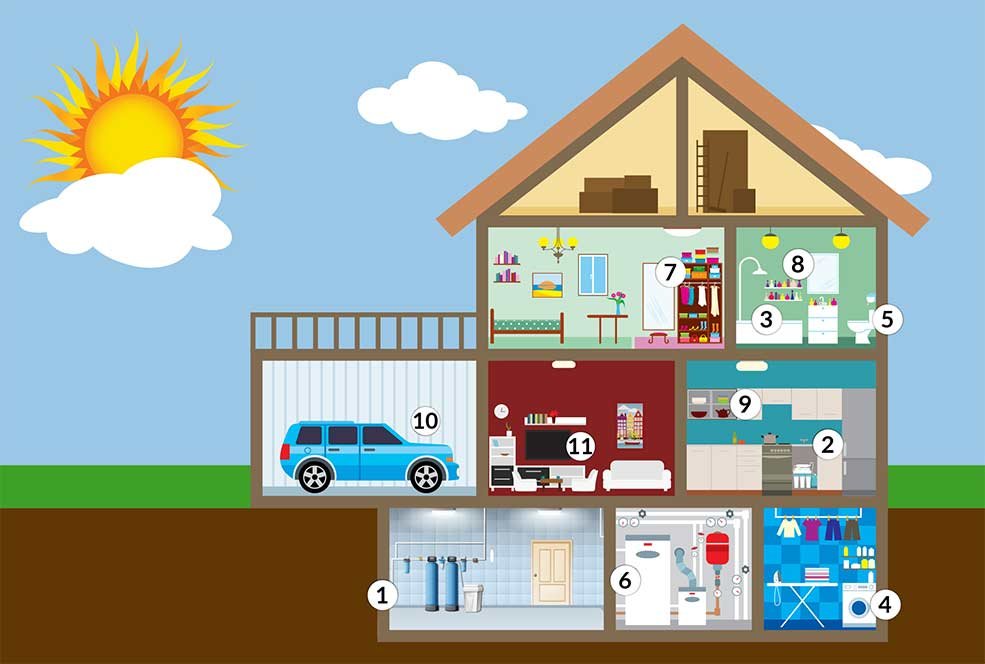

1) Household water supply pipes (expected lifespan: 25-70 years)

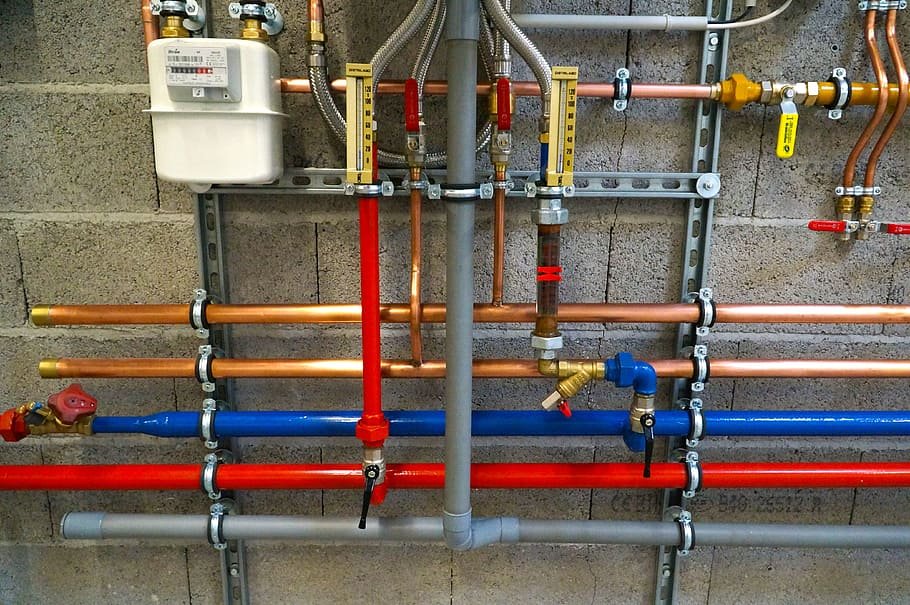

- Typical materials: PPR pipes (mainstream), copper pipes (high-end), PEX pipes (floor heating)

- Advantages: Stable water quality (pH 6.5-8.5), mild pressure (0.2-0.6MPa), and controllable temperature

Fatal weakness:

- • The embrittlement rate of PPR pipes under ultraviolet radiation exceeds 30% in 10 years.

- • Copper pipes may cause the “blue water phenomenon” (copper ion precipitation) when they encounter acidic water (pH<7).

2) Commercial water supply pipes (expected lifespan: 30-50 years)

- Typical materials: 304/316 stainless steel pipe, plastic-lined steel pipes

- High-pressure challenge: The pressure impact during peak water usage in office buildings and hotels can reach 1.0 MPa (more than twice that for household use).

- Disinfectant corrosion: When the chlorine concentration in swimming pools and hospitals exceeds 2mg/L, the risk of pitting corrosion of stainless steel pipes doubles.

3) Industrial water supply pipes (expected service life: 15-40 years)

- • Typical materials: Duplex stainless steel, HDPE-lined plastic pipe

- • Extreme environment: Chemical plant pipelines must withstand 120℃ steam and 5% acid and alkali solutions, with their service life compressed to less than 10 years

- • Main cause of failure: Chemical corrosion (accounting for 68% of industrial pipeline failures, derived from the ASME B31.3 report)

• Data Insight: The same PPR pipe can be used for 50 years in a household, 35 years in a commercial environment, and less than 20 years in an industrial setting – environmental load becomes a life decay multiplier.

2. Household Copper Pipes: The Truth and Pitfalls of a 70-year Lifespan

Copper tubes have become the first choice for high-end home decoration due to their antibacterial properties and high-temperature resistance, but their lifespan is highly dependent on water quality and management.

1) Theoretical lifespan vs. Practical Constraints

| Influence Factor | Ideal Condition | Risk Scenario | Life Expectancy Impact |

|---|---|---|---|

| Water Quality PH Value | Neutral (pH=7~8.5) | Acidic water ( pH<6.5) | 70 years →15 years |

| chlorine residue concentration | <0.5mg/L | Chlorine disinfection of old pipe networks | Perforation risk ↑300% |

| welding technology | Silver brazing + argon gas protection | The solder is poorly soldered | The interface will leak after 10 years. |

2) Longevity evidence

- • The copper pipes installed in the Ritz Hotel in London in 1906 are still in service today (118 years) after regular cleaning.

- • Sampling of copper pipes in historic buildings on the Bund in Shanghai showed that 82% of the pipes had wall corrosion less than 0.1mm after 60 years of use (data source: Building Science 2021).

3) Iron law for maintaining household copper pipes

- ① Before installation: Test the pH value, residual chlorine, and total hardness of the water quality (install a neutralization filter if the standards are not met).

- ② Every 10 years: Endoscopic inspection of elbow weld points (with a focus on checking for blue-green rust spots)

- ③ Change signal: The water output remains bluish-green continuously, and the water flow weakens in segments (indicating that the inner wall scaling rate is greater than 30%)

3. Drainage Pipes: Underestimated Lifespan Differences

Although the drainage pipes have no pressure-bearing requirements, the corrosiveness of the sewage leads to a significant difference in their service life:

- • Household PVC drainage pipe: 30~40 years (high temperature grease in the kitchen causes hose deformation);

- • Municipal cast iron drainage pipe: more than 80 years (Victorian-era pipes are still in use in Manchester, England);

- • Core difference: Commercial catering drainage requires CPVC pipes (resistant to 90℃), which cost twice as much as household PVC pipes.

4. Scientific Longevity Plan

1) Recommended pipe materials for different applications

| Scene | Recommended Pipe Materials | Effective Utilization Measures |

|---|---|---|

| Household water | copper pipe | A silicon phosphorus crystal scale inhibitor is installed at the water inlet end |

| Commercial central water supply | Stainless Steel Pipe | Install a water hammer absorber |

| Industrial acid and alkali media | HDPE fluorine-coated composite pipe | Cathodic protection + anti-corrosion coating |

2) Warning maintenance list

- • Water supply pipe: When the water pressure fluctuation value is > 0.2MPa every year, a pressure reducing valve must be installed;

- • Drain pipe: Kitchen pipes should be flushed with boiling water every month (to dissolve grease) to avoid a blockage rate of more than 40% within 5 years.

5. Suggestions for Decision-making

- • Copper pipe selection: Wall thickness ≥1.5mm (hot water pipe)

- • Lifespan inspection: 500,000 pressure fatigue tests on commercial pipelines.

- • Economic choice

- ① If the water quality is good (pH>7, residual chlorine <0.5mg/L), the lifetime cost of copper pipes is 22% lower than that of PPR pipes (no replacement required for 70 years);

② Otherwise, PPR+filter is preferred (initial cost savings of 75%)

Conclusion

The lifespan of pipelines is the result of the game between materials science and the environment. Under ideal conditions, household copper pipes can exceed the service life of human buildings, while industrial pipes have to accept the reality that “high-intensity service = accelerated retirement”. Precisely matching the scene requirements is the key to extending the lifespan of pipelines.