What is the galvanized pipe?

The galvanizing pipe is divided into hot-dipped galvanizing and electro galvanizing.

Why Galvanized?

Compared with other metals, zinc is a relatively cheap and easy-to-coat metal, which is a low-value anticorrosion coating. It is widely used to protect iron and steel parts, especially to prevent atmospheric corrosion. It can improve the corrosion resistance and service life of steel, it also adds a decorative look to the product.

Because zinc is resistant to change in dry air and is more likely to produce an alkaline zinc carbonate film in a humid environment, the film protects the internal parts from corrosion, even if the zinc coating is damaged by some factor, the combination of zinc and steel over a period of time forms a microbattery, which protects the steel substrate as a cathode.

Every year, about one-tenth of the steel, is corroded, so to protect the service life of the steel or its parts, the steel is usually treated by galvanizing.

What is hot-dip galvanizing?

Hot-dip galvanizing is to pickle the steel pipe and remove the iron oxide and rust on the surface of the steel pipe. It is then cleaned in the tank with an aqueous solution of ammonium chloride or zinc chloride or a mixture of ammonium chloride and zinc chloride, finally, the whole steel pipe is dipped in a hot-dip galvanizing tank. Hot-dip galvanizing has the advantages of thick zinc coating, uniform coating, strong adhesion, and long service life.

What is electro galvanizing?

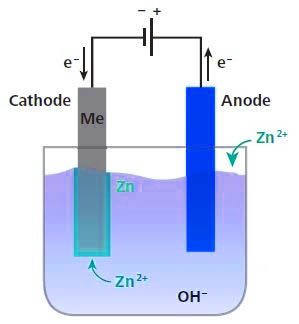

Electro galvanizing, also known as cold galvanizing in the industry, is the process of forming a uniform, dense and well-combined metal or alloy deposition layer on the surface of the workpiece by electrolysis.

Galvanizing can increase the corrosion resistance of steel pipe, can prevent rust, prolong the service life.

The galvanized pipe is also used as a water pipe, but after a few years of use, it will produce a lot of rust. The yellow water will not only contaminate the sanitary ware, but will also cause bacteria to grow on the inside walls, and rust will cause the heavy metal content in the water to exceed the standard, further harm to human health. China’s Ministry of Construction prohibit the use of galvanized pipe as water pipe since 2000.

Advantages and disadvantages of hot-dip galvanized pipe

Pros: hot-dip galvanized pipe can not rust for 10 or even 20 years, the best model product is the high-voltage pylon, have you ever seen the high-voltage pylon rust? (Of course, the high-voltage tower galvanized layer than the high-temperature galvanized pipe, so not easy to rust, and greenhouse pipe can also guarantee 10 years of non-rust)

Cons: high price

Advantages and disadvantages of electro galvanizing

Pros: low price.

Cons:

- They have a short life span of only 5 years. The amount of galvanizing is very little, only 10-50g/M2, its corrosion resistance is much worse than that of hot-dip galvanizing pipe.

- The zinc layer of the cold galvanized steel pipe is separated from the steel pipe matrix. The zinc layer is thin, the zinc layer is simply attached to the steel pipe matrix, easy to fall off. Therefore, its corrosion resistance is poor. It is forbidden to use cold galvanized steel pipe as water supply pipe in the new residence.

- The surface is not very smooth — there are black gaps in the joints because the tube is not galvanized. (electro galvanizing is done on the outer wall only, hot-dip galvanizing both inside and outside.)

The normal manufacturer does not use electric galvanizing mostly in order to ensure quality.

Only small scale, equipment obsolete small enterprises use electro galvanizing, of course, their prices are relatively cheap.

Construction ministries in many countries have banned the use of cold-galvanized pipes with outdated technology as water and gas pipes.

How to identify galvanized pipe quality?

- Hot-dip galvanized pipe, the color is silver shiny, one end of each bend feels a little rough (the reason is that when the hot-dip galvanized pipe is dipped in the galvanized pool, the plating is finished, the crane lifts one end of the steel pipe to air dry, zinc liquid naturally flows down from the top, easy to form a rough end)

- cold galvanized pipe, white and black, there are black cracks in the inner wall of the steel pipe (in fact, there are gaps in hot-dip galvanized pipe, but all blocked after galvanizing, no longer see the black gap)

Application

Galvanized pipe uses is very wide, in addition to a generally low-pressure fluid such as water, gas, oil line pipe, also used as the oil industry, especially the ocean oil field oil well pipe, oil pipe, chemical coking equipment of oil heater, the condensing, exchange of coal distillation wash oil cooler for tube, and trestle pile, mining tunnel supporting frame tube, etc.

Hot-dip galvanized steel pipe is widely used in construction, machinery, coal mine, chemical industry, electric power, railway vehicles, automobile industry, highway, bridge, container, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery, and other manufacturing industries.

Inherent disadvantages of galvanized pipe

Galvanized pipe is now mainly used for gas, heating. Most of the old houses used galvanized pipes as water pipes. After a few years of use, a lot of rust and scale were produced in the pipes. The yellow water flowing out not only polluted the sanitary ware but also mixed with bacteria bred in the uneven inner wall. The heavy metal content in water caused by rust is too high, which seriously endangers human health

This is because the galvanized pipe in use process, will produce large amounts of salts material, gas, and all kinds of suspended solids, the presence of these substances can cause problems, such as deposition, corrosion system operation after a period of time will have a lot of calcium magnesium carbonate scale, sulfate scale phosphate, silicate scale, scale and corrosion products, etc., this dirt firmly attached to the wall and system inner surface, Lead to heat transfer deterioration, increase in coal burning, affect the operating efficiency of the system, cause large economic losses, especially some corrosive liquids, will bring serious harm to the safe operation of the system.

How to clean galvanized pipe?

General GI pipe cleaning methods include the following:

Alkaline scrub, alkaline immersion, electrolytic cleaning, hot water rinsing, etc., can control the stains on the galvanized pipe very low, and will also grind on the surface, so as to reduce the surface adhesion of the steel pipe and increase the service time.

In addition, there are also professional rust and scale removal industrial cleaning products on the market, the effect is perfect, the price is cheap, there may be two problems:

- May remain some harmful substances

- It may damage the galvanized pipe after washing, leading to faster rust later.

Therefore, for galvanized pipe, it is recommended to use a professional pipe cleaning machine to clean, do not add any cleaning agent.