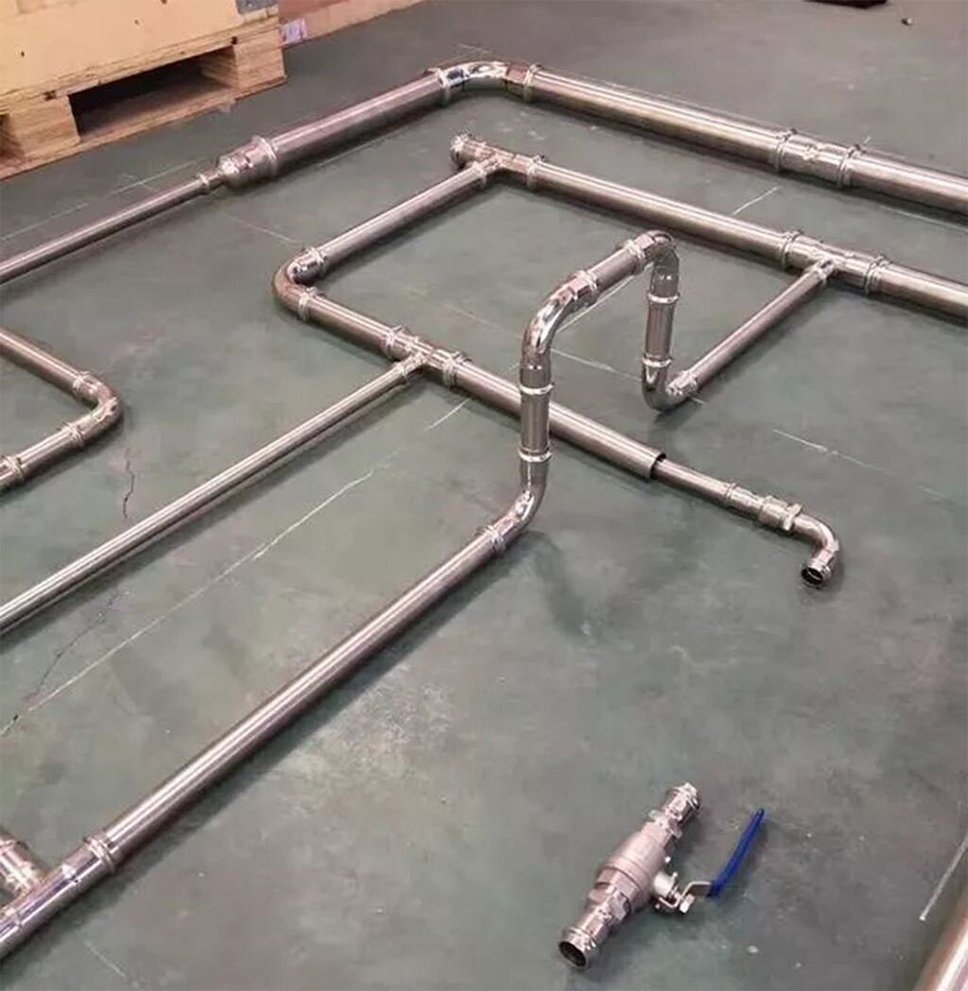

Japan’s tap water supply pipe goes on a standardized track

Before 1955, galvanized pipe was widely used in Tokyo, Japan. From 1955 to 1980, plastic pipes and steel-plastic composite pipes were widely used. Although the problem of water quality and leakage of galvanized pipes has been partially solved, the leakage of the Tokyo water supply network is still very serious, the leakage rate reached an unacceptable 40% ~ 45% in the 1970s, and the “hidden danger water” problem is gradually reflected, plastic pipe and steel-plastic composite pipe can not meet the basic requirements of environmental protection.

According to the analysis, 60.2% of the leakage is caused by the lack of strength of the pipe material under the action of external force, 24.5% of the leakage was caused by the unreasonable design of the pipe joint, and 8.0% of the leakage was caused by the unreasonable design of the pipeline due to the high expansion rate of plastic. To this end, the Japan Watercourse Association recommends the improvement of water pipe materials and connections.

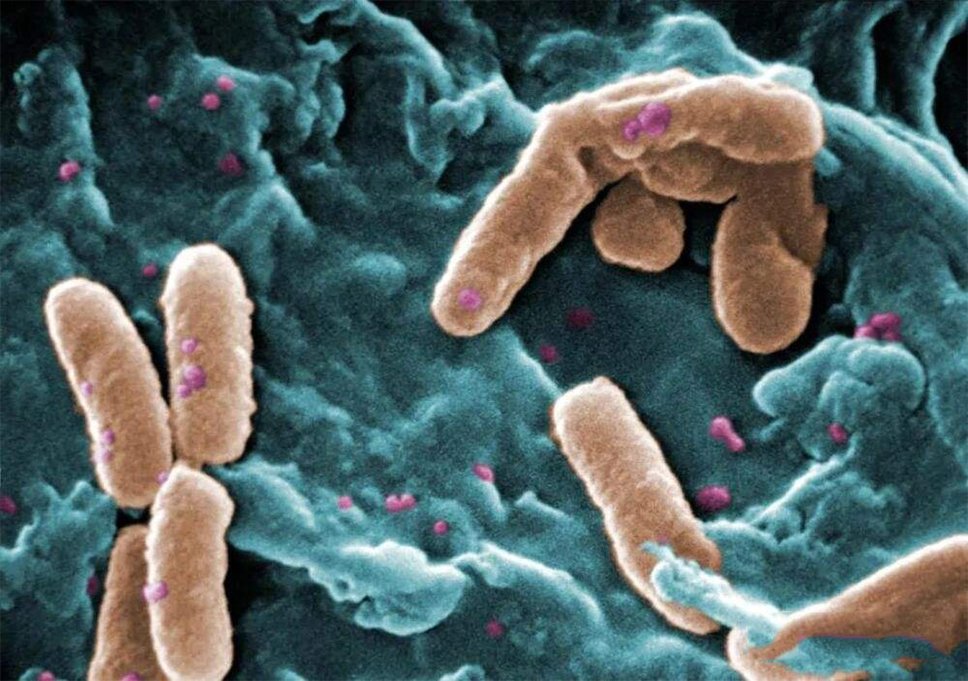

Since May 1980, all water supply pipes below 50 mm in diameter have been made of stainless steel pipes, pipe joints bend, and faucets. In the 1990s, especially after the outbreak of 0-157 pathogenic E. coli poisoning in 1996, people pay more attention to the water quality. In 1999, the Tokyo Water Supply Bureau adopted stainless steel pipe as the standard material, which shows that the stainless steel used as tap water pipeline and water supply pipeline in the building has stepped into the standardized track. According to Tokyo Water Department statistics, with the stainless steel rate from 198211% to 2000 more than 90%, the number of leaks correspondingly decreased from more than 50,000 per year at the end of the 1970s to 2-3 in 2000(due to leakage at joints caused by stray current). The adoption of stainless steel pipes has greatly reduced the leakage rate of water. Now in Tokyo, Japan, the stainless steel pipe penetration rate has reached almost 100%, all residential areas have installed stainless steel pipes, greatly improved water quality.

It has been 40 years since the stainless steel pipe was used in Japan. Now stainless steel pipe has been recognized by the Japanese as the “best drinking water content material.”

US government promotes stainless steel water pipe development

The use of stainless steel pipes in the United States began in the 1960s and flourished in the 1990s. The United States Environmental Protection Agency regulates the selection of materials for water pipes, which must meet the requirements of high water quality, low maintenance, and long service life. The United States government’s National Standard/National Health Fund International Standard ANSI/NSF61-1997A, established under the Water Purification Act of 1996, specifies that “only stainless steel and ductile iron pipes shall be allowed for the use of metallic piping for potable water.” Stainless steel pipe and ductile iron are used for main pipe reconstruction, and stainless steel pipe is the first choice for water supply pipe entering the high buildings. The latest 2003 edition of the American International Standards Commission’s water and residential standards again includes this aspect, indicating that the use of stainless steel water pipes has been officially approved by the United States. Other countries such as Health Canada, the Dutch Board of health accreditation, and the WHO have also confirmed the standard. As a basis for health assurance, more and more countries now require piping and system components of drinking water systems to meet the above-mentioned standards. The first batch of materials to meet the requirements of the standards are 304/304L and 316/316L stainless steel.

In the United States, stainless steel has been successfully used in more than 100 drinking water treatment plants and delivery systems. New York’s water supply has been stainless steel since the 1960s. Based on a 15-year assessment of alternative materials, the city’s old drinking water distribution system failed to meet demand, in 1993,304L stainless steel was used on a large scale in large-diameter vertical column pipes and other pipes of urban water pipelines, with the aim of making the system live up to 100 years. The Washington area water supply renovation also uses stainless steel pipes on a large scale. The water main of the Ford Stadium, a new $300 million stadium in Detroit, is made of 304 stainless steel, including straight-through drinking water pipes from various outlets. In addition, stainless steel pipes have become standard in more than 1,600 new Sewage Treatment cities in the United States over the past 30 years.

The reason why the United States chose stainless steel is purely based on economic and health considerations, stainless steel materials meet the Environmental Protection Agency (EPA-RRB- guidelines, are often used for water quality requirements and are difficult to replace, require low maintenance, the long service life of the occasion. Although the first material cost is about 20% ~ 50% higher than the galvanized pipe, due to the excellent corrosion resistance of stainless steel, the installation, and processing costs are greatly reduced, and the daily operation and maintenance costs of the pipeline are also greatly reduced, and water systems can last up to 100 years, so the total cost over the life of the system is minimal. More than 30 drinking water treatment plants in the United States have replaced ductile iron pipes with stainless steel, mainly because of cost savings. The Massachusetts water plant saves about $50,000 by using stainless steel pipes, compared with ductile iron, and the 30-year-old stainless steel pipes are as shiny as ever.

Stainless steel water pipes are becoming popular in Europe

In some old European cities, the main water supply pipes are asbestos-cement pipes and cast-iron pipes, and water losses due to leakage are as high as 40 percent. Starting in 1980, Germany began to use a large number of stainless steel in the water system to save water resources. The 2006 FIFA World Cup, one of the world’s most prestigious sporting events, uses stainless steel pipes for most of its water supply, because stainless steel has the most stable and reliable performance, clean sanitation, can fully meet the German construction standards for drinking water pipes must have at least 50 years of life requirements.

Since 1995, Italian cities have generally replaced their main water pipelines with stainless steel pipes. Experience has shown that stainless steel pipes are corrosion-resistant, have high strength, and are able to withstand ground subsidence and earthquakes. Their service life is at least 70 years, it is more economical than plastic pipes and other substitute pipes.

In the past, copper pipes were used in Britain, but the soft water quality in Scotland led to the corrosion and failure of copper pipes, resulting in serious water leakage. The government spent a lot of money to study the cause of failure and solutions, and later all the hot and cold water pipes were replaced with stainless steel pipes and joints. After more than 10 years of use, the cold and hot water pipes were disassembled to investigate the use of the stainless steel pipes and joints. The results showed that the stainless steel pipes and joints were in excellent condition and showed no signs of corrosion.